As riders push eBikes to their limits—navigating city streets, rugged trails, and steep inclines—cable integrity becomes paramount. Signal wires, power leads, and brake cables must remain fully functional under vibration, moisture, and abrasion.

Traditional cable sleeving materials often fall short in demanding environments. Enter PTFE heat shrink tubing: a high-performance solution that significantly enhances the protection and longevity of eBike cabling.

Table of Contents

Understanding the Challenges of eBike Cable Protection

eBike cables face a unique combination of stresses:

- Mechanical Abrasion: Cables routed along the frame or suspension components can rub against sharp edges or moving parts.

- Vibration Fatigue: High-frequency vibration from the motor, road surface, and rider weight can cause micro-cracks and wear.

- Thermal Exposure: Motors, controllers, and batteries generate heat; cabling near these components must withstand temperature fluctuations.

- Moisture and Chemical Resistance: Rain, mud, and cleaning solvents threaten cable insulation and conductor integrity.

- Space Constraints: In tight frame designs, protective sleeving must be thin yet robust.

Any breach in cable insulation risks short circuits, signal degradation, or sudden loss of braking control—safety hazards that no rider wants to encounter.

What Is PTFE Heat Shrink Tubing?

Polytetrafluoroethylene (PTFE) is a fluoropolymer renowned for its exceptional chemical, thermal, and electrical properties:

- High Temperature Resistance: Operating range from –200 °C to +260 °C.

- Low Coefficient of Friction: PTFE surfaces are self-lubricating and resist wear.

- Chemical Inertness: Unaffected by acids, bases, solvents, or UV exposure.

- Excellent Dielectric Strength: Superior electrical insulation even at thin wall thicknesses.

When fabricated into heat-shrinkable tubing, PTFE combines these material advantages with the tight conformal fit of heat shrink:

- Expanded Form: Tubing is manufactured to a larger diameter.

- Application: Slide over cable assemblies.

- Heat Activation: Upon heating (typically 250–350 °C), the tubing recovers its original diameter, creating a snug seal.

- Seal Formation: The tube grips tightly around irregular shapes, filling gaps and voids.

Key Benefits for eBike Cable Protection

1. Conformal Coverage and Mechanical Protection

The heat-shrink action ensures the PTFE tubing closely follows each cable’s contours, eliminating loose sections that could snag or abrade. Once cooled, it forms a tough, seamless layer that guards against cuts, nicks, and wear from frame components or debris.

2. Vibration Damping and Fatigue Resistance

PTFE’s inherent flexibility allows the tubing to absorb vibration rather than transmit it directly into the cable insulation. Over time, this reduces the risk of conductor fatigue and micro-fractures in signal wires, maintaining reliable throttle and brake signals.

3. Thermal Stability in High-Heat Zones

Around motor windings and battery packs, temperatures can spike. PTFE heat shrink maintains its structural integrity where PVC or nylon sleeves would soften, melt, or become brittle. This ensures uninterrupted electrical insulation even under thermal cycling.

4. Chemical & Moisture Barrier

Riders encounter water, mud, oils, and cleaning chemicals. PTFE’s non-reactive surface repels moisture and corrosive agents, preventing insulation breakdown. It also resists mold and mildew growth in damp environments.

5. Electrical Insulation & Dielectric Strength

Thin PTFE sleeves can deliver dielectric strengths upwards of 20 kV/mm, surpassing many plastics. This allows for slimmer protective layers without sacrificing safety, crucial for neat cable routing on compact frames.

6. Longevity and Environmental Resilience

PTFE does not degrade under UV exposure, meaning external cabling on step-through frames or exposed down tubes retains its protective qualities for years. Its low friction also inhibits accumulation of dirt and grit, simplifying maintenance.

Practical Application on eBikes

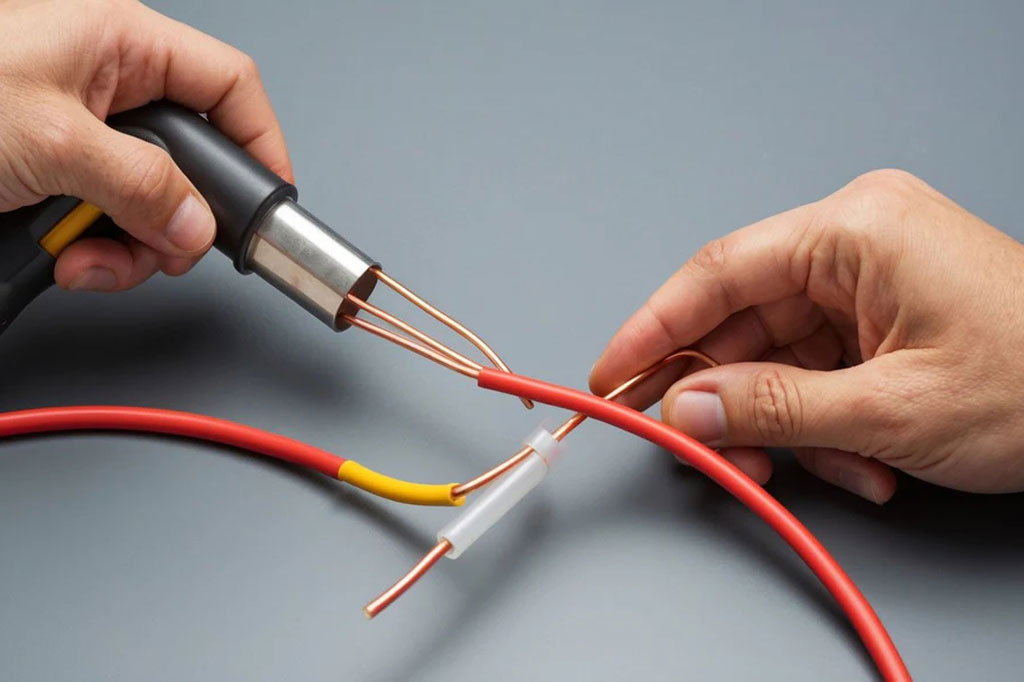

- Preparation:

- Clean cable surfaces to remove grease, dirt, and old sleeving.

- Cut PTFE heat shrink tubing to length, allowing for 5–10 mm overlap at each end.

- Installation:

- Slide tubing sections onto cables before final cable-end fittings are attached.

- Position tubing over high-stress zones: around brake cable housings, throttle lines, motor power leads, and junction block areas.

- Heat Shrink Process:

- Use a controlled heat gun (adjustable up to 350 °C) or an oven for uniform heating.

- Apply even heat, maintaining a 5–10 cm distance to avoid scorching adjacent components.

- Observe the tubing contracting and conforming; continue heating until recovery is complete.

- Post-Installation Inspection:

- Check for gaps or unshrunk sections.

- Gently flex assembly to ensure the PTFE layer moves smoothly without separation.

Case Studies & Performance Data

- Mountain eBike Trials: Riders using PTFE-sleeved brake cables reported a 30% reduction in service calls due to cable failure over six months of trail riding.

- Urban Commuters: A fleet of electric delivery bikes outfitted with PTFE heat shrink on power leads experienced zero controller faults in rainy conditions over a one-year period.

Considerations and Best Practices

- Heat Source: Avoid open flames; use industrial heat guns with ceramic elements for temperature accuracy.

- Sizing: Select shrink ratio (commonly 2:1 or 3:1) appropriate to cable diameter; too much shrink may stress tubing, too little may leave gaps.

- Compatibility: Ensure PTFE tubing’s recovery temperature is compatible with surrounding materials—mountain bike frames or components should tolerate the heat gun’s peak temperature.

- Cost vs. Benefit: PTFE heat shrink tubing costs more than standard polyolefin, but its durability and reduced maintenance often offset initial investment for serious riders.